Close

Blog Categories

Archives

Latest Posts

A company operating in the metalworking sector has chosen to replace its plastic keyboards with other silicone keyboards. That's why the TS308 is the right solution for your needs.

An important metalworking customer from the province of Vicenza performs bending and cutting of sheet metal using large industrial machinery and has always used classic desktop plastic keyboards even if they were not suitable for its sector.

In this specific case, the customer also had a difficulty regarding the size of the keyboard, this had to fit perfectly into the work surface, not exceeding the dimensions 450x140 mm.

For the customer, therefore, the most suitable choice could only be a silicone keyboard as:

After these considerations we focused on identifying a product that respected the dimensions requested by the customer and the TS308 model keyboard was suitable for all its specifications.

You can find the keyboard features by clicking this link.

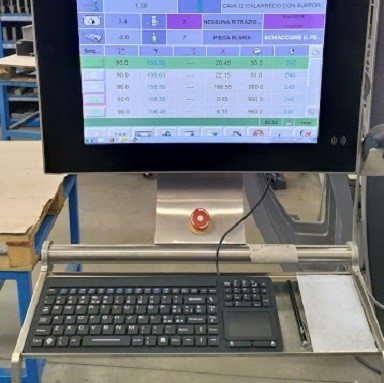

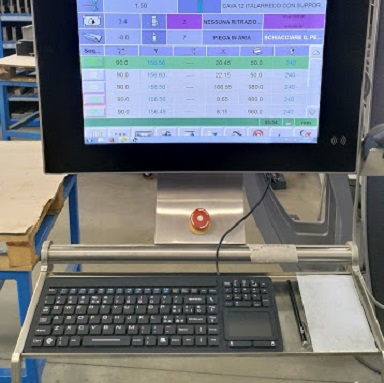

Below is the work plan with the chosen industrial keyboard:

*************************************

If you don't know which keyboard is best suited to your needs or if you want a custom quotation

and we'll answer you in a very short time

*************************************

Comments (0)

No comment